PCB Through Hole Plating Line Automation

Why is this done

What is the point of doing this kind of automation system for pcb through hole plating machine. Is there a point? What do we gain by doing this?

Background

Background research maps the current situation of pcb through hole plating system automation. On commercial scale there are automated systems but what is the situation in prototype manufacturing.

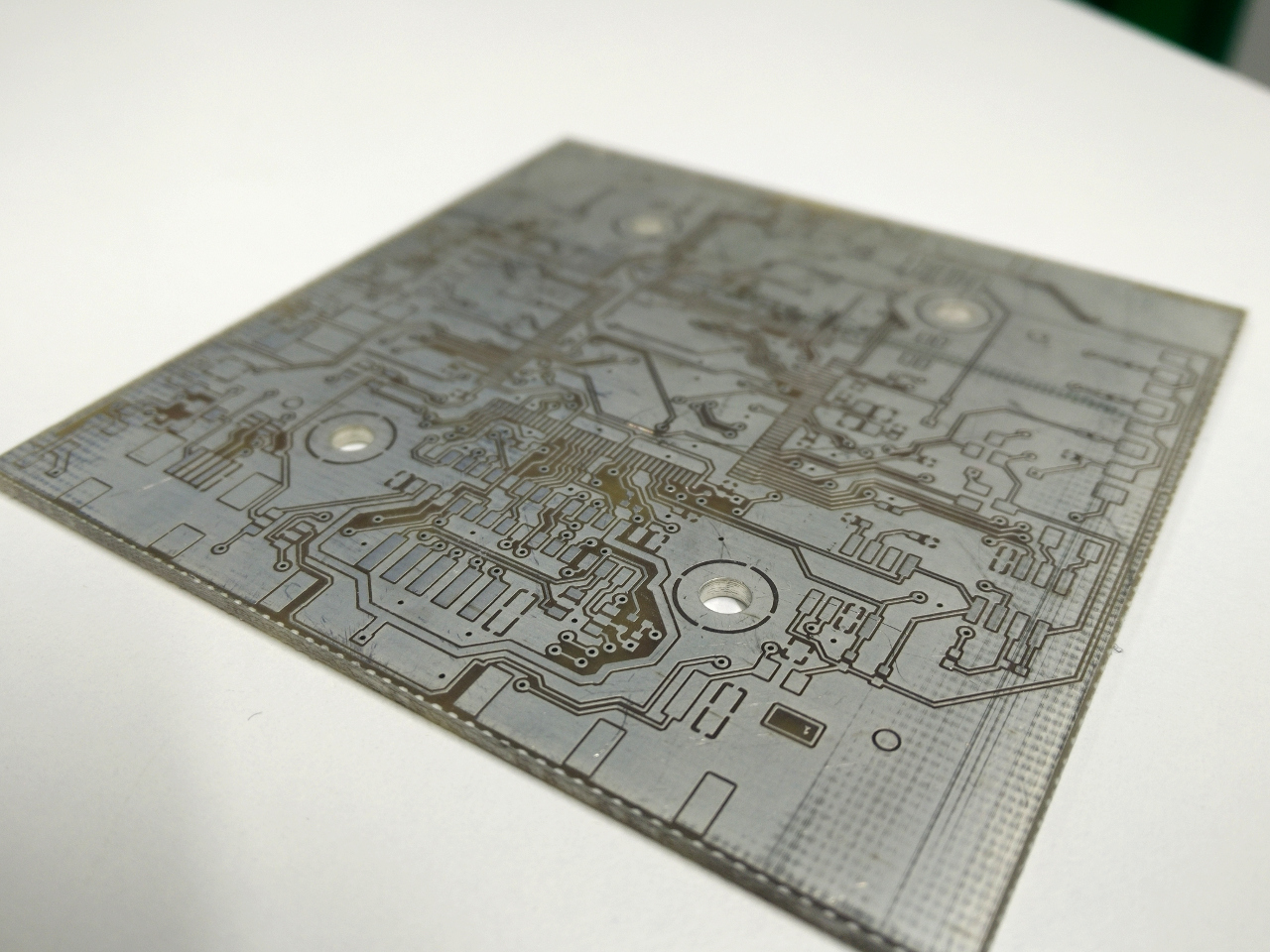

Through hole plating

To make multilayered printed circuit boards, a connection must be made between layers. This can be done in few different ways.

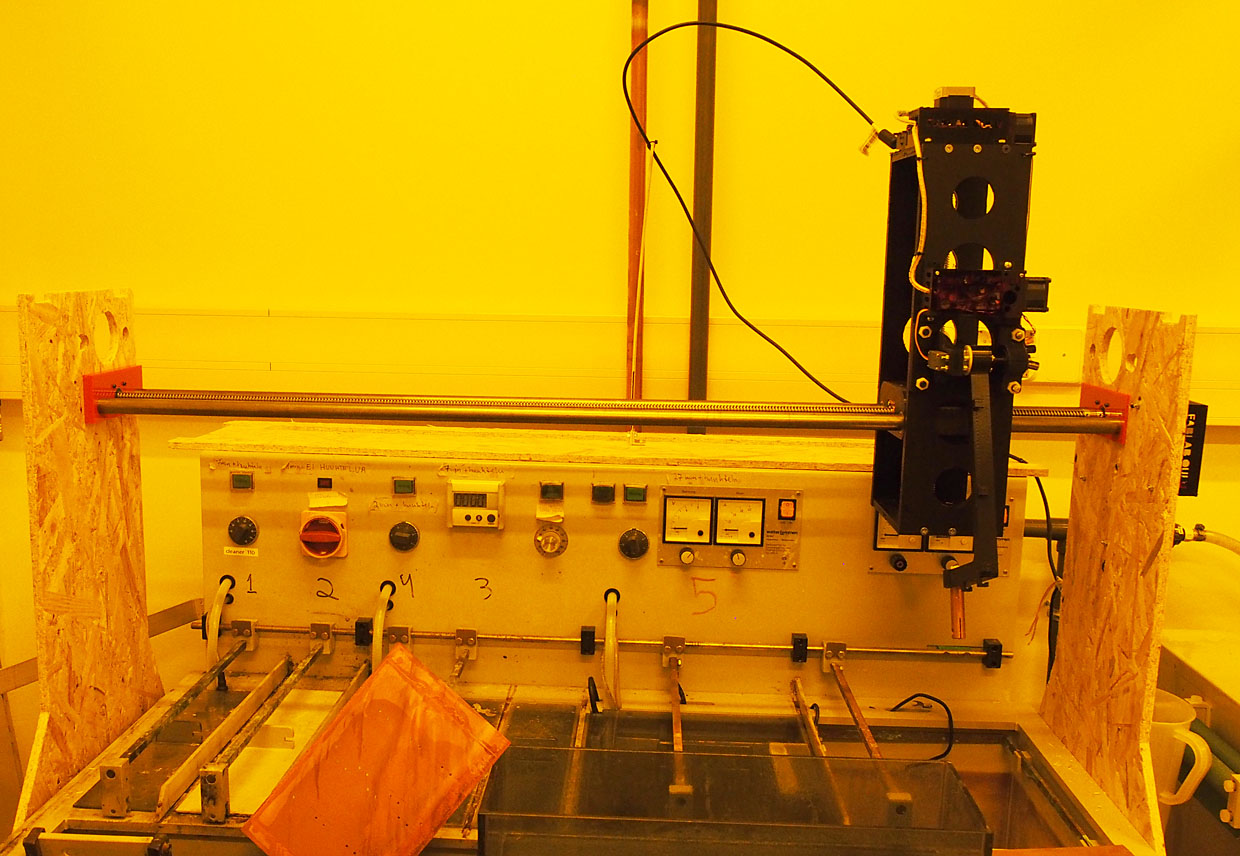

Case Oulu university PCB manufacturing

Even there are elements on this project that have generalization purpose, the main goal is to automate the inhouse pcb manufacturing machine. It will be used as test bed for the process and ultimately used in everyday manufacturing.

Electronics design

One goal of this project is to develop a general stepper motor controller using fab inventory components. This will support the fab networks as well as my personal project.

Mechanical Design

This project need 2-3 mechanical moving axis. They will be done in different styles to learn of different types. Also generalization is considered to fulfill need of fab network goals.

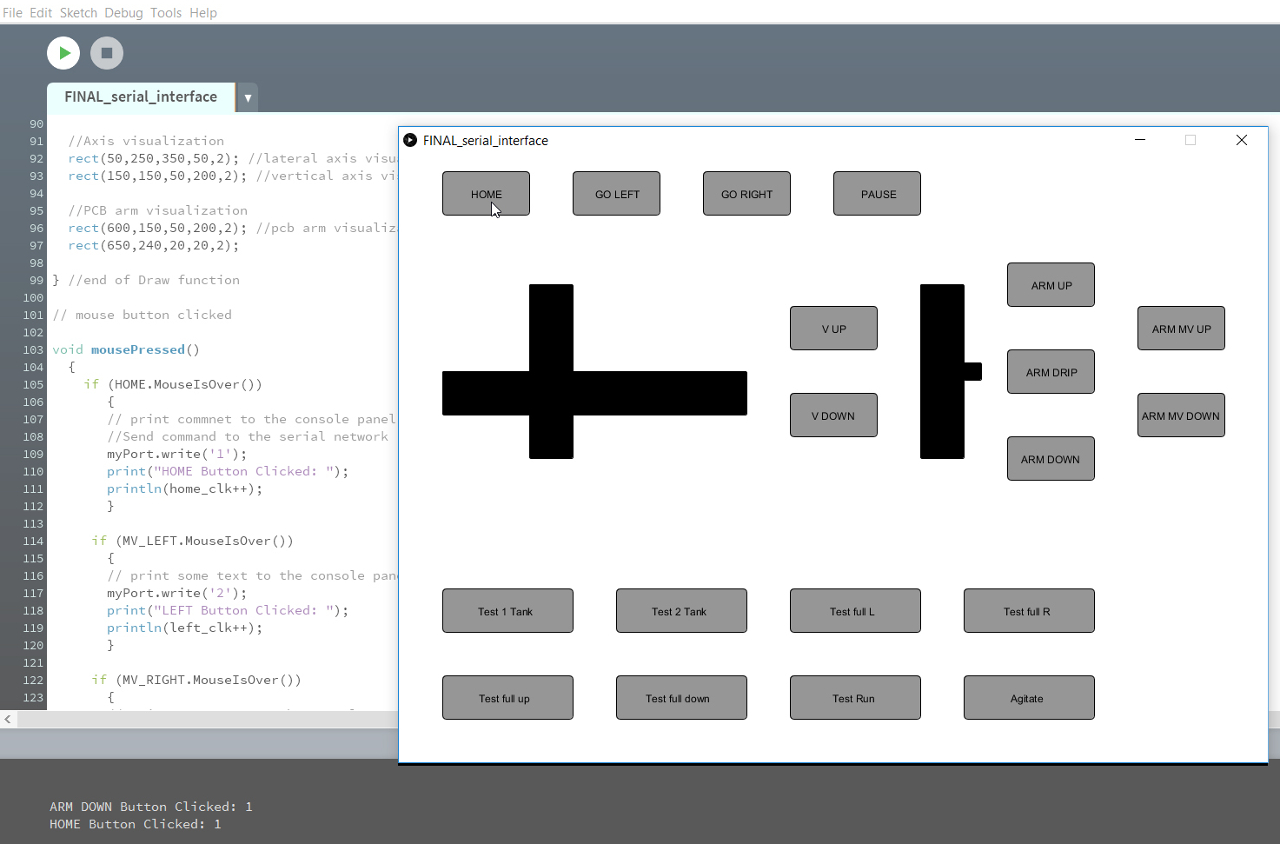

Software and user interface

This machine will be run with quite simple mechanical user interface. For the generalization of the automation system computer based UI is made as well.

High power component integration

Original machine uses 220V. This has to be connected to the build automation.

Do almost anything